Domed Stickers: Your Guide to the Best Solutions

What are 3D domed stickers?

A domed sticker is a special sticker whose surface is covered with a resin layer. Thanks to their unique shape and high-quality materials, three-dimensional stickers attract customers’ attention. The graphics on the sticker gain a three-dimensional effect, looking as if they were slightly convex. The process of creating such a sticker is called doming.

Doming is a technique that covers a printed graphic with a polyurethane resin layer. This creates a relief effect, giving the product a three-dimensional appearance.

3D Stickers

Domed stickers, also known as 3D domed labels or doming badges (also: 3D stickers, dome stickers, doming stickers, etc.), are advertising graphics that use special 3D sticker coating technology to create the illusion of three-dimensionality. Using different materials and layers, such stickers attract attention with their unique appearance and encourage touch thanks to their texture. These stickers can be printed on various types of substrates, such as self-adhesive foil, transparent, silver and gold, which allows for a wide range of applications in producing 3D stickers.

Dome stickers are 3D stickers made of resin, characterised by high resistance to weather conditions and mechanical damage.

3D domed stickers (doming) are often used for marketing purposes (advertising stickers), on products, packaging, or as decorative elements. They are an excellent way to increase brand recognition and improve marketing themes. Their main advantage is distinguishing a brand or product from the competition and adding a new dimension to traditional advertising methods.

Thanks to the precision of the production process and the use of high-quality materials, 3D domed stickers are visually attractive but also durable and long-lasting.

Where does the name “doming” come from?

The name “doming” comes from the word “dome” (from Latin domus), which describes a shape similar to the hollow upper half of a sphere. This directly references the doming technology’s effect – resin-coated prints have a three-dimensional, domed shape. This term effectively describes the characteristics of this technology, emphasising its ability to create spatial effects. Domed 3D stickers are a notable example of this technology.

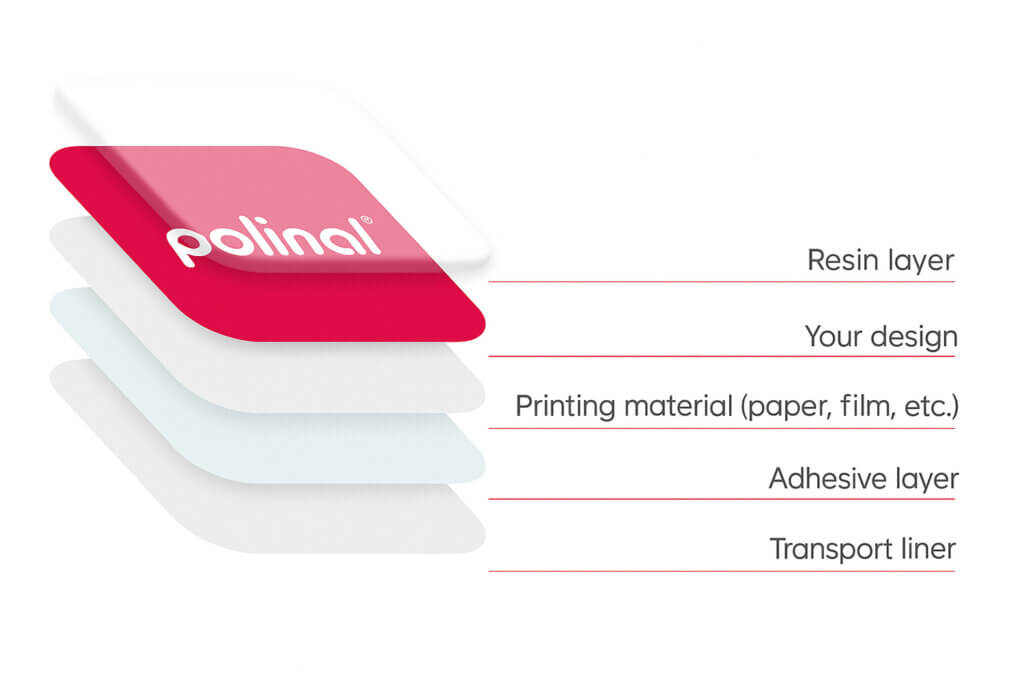

What layers is a dome sticker made of?

Resin layer

After the paint has been applied and dried, the raised stickers are covered with transparent polyurethane resin. The resin creates a three-dimensional “drop” effect (hence the name “doming”), which additionally protects the print from damage.

Print layer

Using digital, screen or offset printing, a colour print is applied to the foil. Various types of paints are used here, which must be resistant to abrasion and exposure to

Base – printing material (paper, film, etc.)

It is most often a self-adhesive foil on which a pattern is printed. The base is made of various plastics, including PVC, PET, polyethylene, and holographic foil. This foil is intended to ensure the durability and adhesion of the sticker.

Adhesive layer

On the underside of the self-adhesive foil is a layer of glue that allows for multiple peeling and sticking of the sticker to different surfaces (sticker adhesion). This glue must be both strong and durable, yet safe for the surface to which the sticker is adhered.

Protective layer – transport liner

The last layer is a protective film or paper. It protects the adhesive from drying out and contamination. It is removed just before the sticker is applied.

Each of these layers serves a distinct function, resulting in a product with a unique appearance and properties.

The history and development of domed sticker production technology

The beginnings of the production of domed labels.

The first raised stickers were produced in the 19th century using casting and embossing techniques. They were hand-painted and used mainly for decorative and advertising purposes.

Development of dome sticker production technology (doming)

Evolution of technology and production methods:

In the 20th century, the production of 3D stickers gained popularity thanks to the development of new technologies such as offset printing and machine embossing.

- The introduction of flexographic printing in the 1960s enabled the quick and efficient production of large quantities of dome stickers.

- The development of laser technology in the 1980s enabled the precise engraving of patterns on matrices, resulting in higher-quality stickers.

- In the 21st century, new technologies, such as digital and 3D printing, offer even greater possibilities for producing 3D stickers. Additionally, laser-cut engraving laminates allow the creation of three-dimensional stickers with vivid colours, UV resistance and durability.

Production began in the 1960s, when the thermoforming technique was first used to create images with raised relief. This innovative method allowed for a unique visual effect and quickly gained popularity among producers and consumers.

The development of technology and materials used to produce stickers has made them more accessible and affordable to a wider audience. As a result, convex stickers have begun to gain ground, finding use not only as decorative elements but also as marketing and identification tools.

Doming sticker production trends – innovations and the future

Innovation and the future of the product

Domed stickers, although known for some time, continue to evolve in response to the growing market demands and technological advancements. Here are some trends and innovations that are shaping the future of this product:

Mass personalisation: Thanks to modern digital machines, personalising doming stickers is becoming increasingly accessible and cost-effective. Customers increasingly expect products tailored to their needs, and 3D convex stickers are an ideal solution. It is also worth mentioning that there are foils with stronger adhesives, such as polymer foil or 3M foil, which enable the permanent adhesion of stickers to various substrates.

New visual effects: In addition to the classic 3D effect, new visual possibilities appear, such as:

- Lens effect: Creates the impression of depth and magnification of the graphic.

- Changing image effect: The graphics look different from different viewing angles.

- Glitter effect: Adds shine and elegance to the sticker.

Smart domed stickers: Combining RFID or NFC technology with domed stickers opens up new possibilities, such as:

- Product identification: Each sticker can have a unique code, allowing the product to be tracked through the supply chain.

- Interactivity: The sticker can be used as an information carrier, displaying additional data after being scanned with a smartphone.

New technologies in production

- Digital printing replaces traditional printing methods, enabling faster production, lower costs and greater design flexibility.

- Automation: The production process is becoming increasingly automated, resulting in increased efficiency and precision.

- New materials: New, more durable, flexible and environmentally friendly resins are emerging.

- Additive technologies, such as 3D printing, create new possibilities for custom sticker shapes and structures.

Ecological solutions and materials

Ecological certificates: Producers are increasingly obtaining certificates that confirm the environmentally friendly nature of their production.

Biodegradable materials: More attention is paid to producing eco-friendly doming stickers using biodegradable materials and resins.

Waste minimisation: Optimising the production process enables the reduction of waste.

Expected trends and development directions

- Miniaturisation: Doming stickers will become increasingly smaller, allowing them to be used on small surfaces.

- Integration with other technologies: Domed stickers will increasingly be combined with other technologies, such as OLED displays or sensors.

- Application in new industries: Resin stickers will be utilised in emerging sectors, including electronics, automotive, and healthcare.

Domed 3D stickers in the context of environmental protection

Ecological materials and production processes

Recycling and biodegradation of stickers are crucial aspects of an ecologically responsible approach to production. Increasingly, companies are introducing recycling programs that enable the reuse of materials used to produce stickers.

Biodegradable resins and films, which can break down in their natural environment, are becoming increasingly available and popular. These innovations can make stickers more environmentally friendly, reducing waste in landfills.

Companies using sustainable practices include Avery Dennison and 3M, which invest in developing sustainable materials and manufacturing processes. Avery Dennison has introduced Greenprint product lines that use recycled materials and reduce CO2 emissions.

Meanwhile, 3 M is developing technologies that reduce energy and water consumption during production while improving material efficiency. These companies are leaders in the push for more sustainable sticker production, demonstrating that innovation can coexist with ecological responsibility.riałów. Firmy te są liderami w dążeniu do bardziej zrównoważonej produkcji naklejek, pokazując, że innowacje mogą iść w parze z odpowiedzialnością ekologiczną.

Applications of 3D domed stickers

Applications in various industries, including marketing sports accessories

- Branding and advertising are used to promote brands and products

- Products – facilitate identification and add aesthetic value

- Decoration and personalisation – used to decorate personal and commercial items

Application in various types of industry

- Automotive industry– 3D stickers with company logo on cars

- Consumer electronics– product labelling and branding

- Home appliances and equipment– marking of machines, marking of household appliances,

- Advertising and marketing industry, 3D advertising stickers, brand promotion, gadget marking, trophy marking, advertising stickers, logo stickers (branding with domed stickers)

- Consumer Products and Personalisation– sports accessories marking, product personalisation, security identification, household appliances marking, trophy marking.

Advantages of 3D stickers

High quality at an affordable price

- Sticker printing is currently one of the most attractive solutions on the promotional market.

- Solvent printing is a technology that enables the creation of 3D labels. It guarantees unprecedented quality and offers competitive prices.

Visual

- 3D effect: They create an attractive, expressive and modern look.

- High quality: The resin coating gives them a luxurious and professional appearance.

- Graphics protection: The resin protects the print against scratches, fading and damage.

Functional

- Resilience: They resist water, detergents and external and atmospheric factors.

- Flexibility: They adhere well to various surfaces, even curved ones.

- Long service life: They retain their appearance for a long time.

Marketing

- They attract attention: Their convex nature distinguishes them from other stickers.

- They build prestige: They add class and value to a product or packaging.

- Increase brand recognition: Their unique appearance makes them easy to remember.

Types of domed stickers

Due to the shape

- Round: The most popular shape, perfect for logos, serial numbers or small graphics.

- Square/Rectangular: Perfect for longer text, graphics or QR codes.

- Irregular: They can take any shape, allowing you to create unique and eye-catching stickers.

Due to the print (base) material

- Transparent film: It gives the sticker a light feel and makes the graphics float above the surface of smooth surfaces.

- White foil: A classic solution ensuring high print contrast.

- Metallic foil: Adds elegance and prestige to the sticker.

Due to the type of resin gel stickers

- Epoxy resin: An older type of material that tends to yellow over time

- Polyurethane resin: Currently the most commonly used, it is characterised by high durability and flexibility and does not show colour changes over time.

Due to the application

- Product stickers – raised labels: Logos, markings, production dates, serial numbers.

- Packaging stickers enhance the product’s attractiveness and facilitate its identification.

- Promotional stickers: They attract the attention of potential customers.

- Information stickers: They are used to convey important information.

Production of 3D domed stickers

3D convex sticker printing

Domed stickers, also known as 3D domed stickers, have become a popular tool in many industries, from automotive to advertising. They are characterised by a three-dimensional appearance that attracts attention and adds an aesthetic dimension to products.

They are created using a special polyurethane pouring technique, which gives the sticker a characteristic convexity and shine. Producing stickers is relatively complex, but it enables you to obtain a high-quality and durable product.

To print a flat base sticker, you can use one of the printing techniques known for foil stickers: offset, digital, or screen printing. Depending on the design, the print can be monochrome or colour.

Stages and technology of producing 3D convex stickers

In the following section, we will discuss some of the most important techniques and steps in the production of dome stickers, so that you can better understand how this eye-catching and popular product is created.

1. Graphic design

The first step in sticker production is creating a graphic design. At this stage, it is crucial to choose the colours and shapes that best represent the brand or product. The graphic design can be created using specialised graphic software that accurately reproduces the sticker’s final appearance.

2. Preparing the matrix

The next step is to prepare a matrix with a duplicated design for printing. The matrix is necessary to precisely transfer the design to the self-adhesive foil and multiply it. This process includes calibrating the equipment to ensure high quality and accuracy of the print.

3. Selection of materials

Various materials are used in the production of 3D stickers, which influence the durability and appearance of the final product:

- Self-adhesive foils: PVC, PET, paper.

- Adhesives: acrylic, rubber.

- Resins: polyurethane, epoxy.

Each of these materials has unique properties, which are selected based on the project’s specific requirements. Adhesive and electrostatic films allow for multiple peeling, making them ideal for smooth surfaces and walls.

4. Printing

The next step is to print the design on the selected self-adhesive foil. Depending on the design requirements, various printing methods can be employed, including offset printing, digital printing, or screen printing. After printing, the stickers are dried to protect the print.

5. Cutting out stickers

After printing, the foil sticker sheets are cut into the appropriate shapes. Cutting plotters or laser devices are used for this. Printed plastics often produce stickers, allowing for deeper and more vivid colours, UV resistance and greater product durability.

6. Applying the resin

One of the most crucial stages in producing doming stickers is coating them with transparent resin. Special automatic devices apply the resin to the sticker’s surface, creating a 3D effect. Automation ensures the perfect repeatability of the polyurethane filling height, which is impossible to achieve in small-scale manual production.

7. Sticker drying stage – resin hardening

The curing process can be performed using UV radiation or thermal methods, ensuring the durability and resistance of the sticker. UV radiation accelerates the curing process depending on the resin used. The dryer must meet high-temperature and high-air-humidity requirements and maintain these parameters at a constant level.

8. Quality control

The final stage of production is quality control. The sheets on which the gel stickers are produced are carefully checked for print accuracy and convex surface quality. Only stickers that meet high-quality standards are delivered to customers.

Domed stickers can also be made from printed plastics, allowing them to be used for branding, logos, advertising slogans, and marking various products. Depending on the project’s requirements, either laser cutting or die cutting can be used for this purpose. Precise cutting is essential for achieving an aesthetically pleasing and functional product.

Overview of materials used in the production of convex stickers

- Self-adhesive foils: PVC, PET, paper – these materials vary in strength, flexibility and resistance to weather conditions.

- Resins: Epoxy and polyurethane – provide durability and a three-dimensional effect. It is also important to consider the dimensions of the sticker, including its shapes, sizes, and materials used in production, such as UV-resistant resins and the convex effect. Hence, the name used is resin stickers.

- Adhesives: Acrylic and rubber differ in adhesion strength and resistance to various surfaces.

Offer for advertising agencies – free product samples

Convex sticker printing

Offset printing is a traditional method that uses metal printing plates to transfer ink onto paper or other material. Its advantages include high print quality, the ability to print large runs at a low price, and ideal for printing complex graphics and photos.

The disadvantages include high initial costs, a long preparation time, and less flexibility compared to digital printing. It is used to produce high-quality, detailed stickers for large brands and advertising campaigns, as well as for premium products.

Digital printing is a modern method that utilises digital files to print directly onto materials. Its advantages include fast production time, low initial costs, the ability to print small runs and high flexibility in personalisation.

The disadvantages are the higher unit price than offset printing and the smaller range of available materials and finishes. Digital printing produces domed stickers for small companies and startups, as well as personalised and short-run stickers with simple graphics.

Screen printing is a technique that uses a printing mesh to apply paint to a material. This method’s advantages include durability and resistance to abrasion, the ability to print on various materials, and it’s ideal for printing large, flat surfaces.

Screen printing’s disadvantages include lengthy production times, high initial costs, and lower image quality compared to offset and digital printing. It is used to produce raised labels for industrial products and machinery, as well as warning and informational labels, and labels for windows and glass.

How to order 3D domed stickers?

- The maximum sticker dimension includes the maximum side length and surface area of the sticker, depending on its shape.

- The flexible UV resin used to produce convex stickers is scratch-resistant and highly resistant to mechanical damage.

- Convex, 3D polyurethane stickers resist external conditions, temperature differences and sunlight.

Practical advice for entrepreneurs

How to Choose a Domed Sticker Supplier

Choosing the right sticker supplier can significantly impact the quality of the final product and the effectiveness of your marketing campaign. When choosing a supplier, it is worth paying attention to a few key aspects.

First, check the references and reviews of other customers to ensure that the supplier is reliable and provides high-quality products. The next step is to evaluate the technology and materials that the supplier uses.

It is worth asking about the types of resins, adhesives, and films used in production to ensure they meet your requirements. Another important aspect is the supplier’s flexibility in personalising orders and lead times.

Ensure your supplier can deliver your stickers promptly and to your exact specifications.

How to Effectively Use Domed Stickers in Marketing Campaigns

A raised sticker can be used effectively in marketing campaigns, provided it is designed and used properly. First, it is worth creating an attractive and legible graphic design that will attract recipients’ attention.

Resin stickers can be distributed as free samples during promotional events (e.g., gadget branding), increasing brand awareness and encouraging product interaction. They can also be used as decorative elements on product packaging, improving their aesthetic value and distinguishing them from the competition.

It is also crucial that stickers are well integrated with other campaign elements, such as advertising materials, websites, or social media, which will ensure consistency and increase the effectiveness of marketing activities.

The most common mistakes and how to avoid them.

Producing and using raised labels can present some challenges, so knowing the most common mistakes and how to avoid them is worth knowing.

One of the most common mistakes is choosing low-quality materials, which can rapidly deteriorate the appearance of the stickers and negatively impact the brand’s image. It is always worth investing in proven and durable materials to avoid this.

Another mistake is the lack of precision in sticker design, which results in illegible or unattractive graphics. It is worth taking the time to carefully plan the project and utilise professional graphic services. The project should strictly define the sticker’s dimensions, the sticker base’s colour (the foil’s), the sticker’s shape, and other elements.

Another problem is improper storage and transportation of stickers, which can damage them before they are used. Stickers should be stored in proper conditions to maintain their quality.

Ultimately, a lack of cohesion in a marketing campaign where stickers are just one element of many can reduce their effectiveness. That’s why all aspects of the campaign must be in sync and complement each other.

Summary

Doming technology transforms ordinary stickers into three-dimensional advertising elements (3D stickers). It consists of covering the stickers’ surface with a transparent layer of two-component polyurethane. This special resin creates a flexible lens that protects the stickers and adds depth to them. The production process consists of four stages: printing, plotting, pouring polyurethane, and curing the resins.

Thanks to the doming technology, stickers are not only more visually appealing but also more durable. Doming stickers are flexible, transparent, and easy to shape, which allows you to create unusual shapes and visual effects.

Labelling products using doming technology is economical and ecological, and machine production ensures repeatability of quality. Many manufacturers in various industries, such as HVAC, HORECA, IT, furniture, construction, and machinery and equipment production, use doming technology to increase their brand recognition and strengthen the company’s perception.

Domed stickers FAQ

-

Does the price of 3D stickers depend on the number of colours?

We most often print digitally. Here, we have a full palette of CMYK colours. The price will be the same regardless of the number of colours.

The same applies to offset printing, which we use for larger print runs. Here, too, you can expect fixed costs, regardless of the number of colours. The designer can show their creativity.

It’s different when a project needs to be printed using screen printing. When does this happen? It’s when we want to achieve interesting effects with mirror foils, such as silver or gold. We also use screen printing when we have a colour from the Pantone palette, which cannot be achieved with digital printing. In this type of printing, costs depend on the number of colours in the project. Each additional colour increases the price due to higher setup costs.

Don’t worry too much about this. We will tailor the pricing offer for 3D stickers to your budget and choose an economical printing technique.

-

How long does it take to produce 3D stickers?

-

- The fastest method is digital printing. We can fulfil orders in as little as 2 to 3 working days. However, due to the number of projects in the queue, production usually takes 4 to 5 working days.

- Screen printing takes a bit longer, typically around 7 working days.

- Offset printing requires more time for preparation, with deadlines reaching up to 10 working days.

Of course, deadlines also depend on the production volume. We recommend delivery in several stages for very large orders to ensure that the first stickers are delivered as quickly as possible.

-

-

Are 3D stickers resistant to water and sunlight?

Yes. The stickers are completely waterproof. Additionally, sunlight does not alter their appearance. Our tests indicate that the raised stickers maintain their look for up to 10 years.

-

How to stick 3D labels so that they don’t come off?

Stick them on clean and degreased surfaces. Flat and smooth. If your product has an uneven surface, consult our advisor.

Apply them when the ambient temperature is at least 15 °C.

After application, the raised labels will achieve full adhesion only after 1 – 2 days. Don’t judge their stickiness based on temporary adhesion, as the adhesive does not bond quickly.

-

How high is the dome of the 3D sticker?

We typically have a height of 2 – 2.5 mm for smaller domed stickers. The risk of overflowing the sticker increases for larger ones, and the average height is 1.5 – 2 mm. Sometimes, clients ask us to make the height as large as possible. We strive to make this the standard. Interestingly, some clients request that we pour the resin for 3D stickers as low as possible. This can also be challenging, as it is easy to end up with unfilled areas. By default, we aim to achieve the highest possible doming, of course, within technical possibilities.

We try to ensure that the doming is as high as possible. This gives 3D labels a distinctive appearance. Much depends on the shape and dimensions of the sticker. We adjust the amount of polymers to ensure a smooth production process. Overflowing sheets slow down production.

-

How does temperature affect 3D stickers?

Always apply 3D labels at a temperature of at least 15 °C. At this temperature, they are flexible and the adhesive bonds well with the substrate. Temperature significantly affects the plasticity of the embossed labels.

High temperatures are not an issue. You can use them on hot surfaces like heating appliances or ovens.

In low or negative temperatures, the labels lose their plasticity and ease of use. In winter, embossed stickers are transported in low temperatures, so after delivery, leave them for 2 hours at room temperature. They will regain their flexibility and ease of application. Temperature does not harm them in any way, but using them immediately after delivery may be challenging.

-

How long can I store 3D stickers before using them?

A maximum of two years. If you plan to use the labels within two years of ordering, it’s worth ordering a larger quantity. If you keep the domed stickers at room temperature, the film will retain its full properties. The print will also look the same. Take advantage of this opportunity and save money.